A wide range of accessories, such as inline dispersers and cleaning cells, provide a so-called “process interface” for adapting the measurement probe to different conditions within the process.

The option of dispersing the particle flow within the process vessel sets Parsum probes apart from other inline measuring systems. Inline dispersing is the only way of ensuring particle size determination in damp, sticky, electrostatically charged or otherwise complicated materials in a reliable manner and in a way that is comparable with laboratory processes.

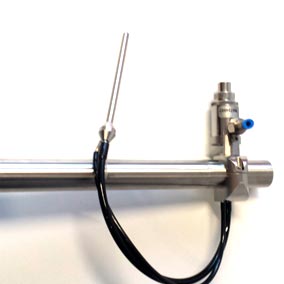

The cleaning cells use compressed air to keep the optics free of particle deposits, thereby significantly reducing the cleaning frequencies. Inline dispersers dilute the particle flow using compressed air, while simultaneously preventing deposits and blockages on the optics. A hard-chrome-plated protective tube means that the probe can be used even with particularly abrasive materials such as silicon carbide or corundum.

To carry out the measurement, compressed air is used to extract the material from the process chamber or bulk material, with the option of then feeding it back in once the measurement is complete. As well as transporting the material, special nozzle arrangements within the probe tube also ensure a gentle dispersion of the material. This treatment ensures that the material can be reliably measured even under difficult conditions.

To carry out the measurement, compressed air is used to extract the material from the process chamber or bulk material, with the option of then feeding it back in once the measurement is complete. As well as transporting the material, special nozzle arrangements within the probe tube also ensure a gentle dispersion of the material. This treatment ensures that the material can be reliably measured even under difficult conditions. In this way, the probe does not come into contact with the product. The measurement is carried out through the glass tube without contamination. The measurement can be carried out continuously online by extracting the liquid from a process vessel or process line in a bypass flow, and feeding it through the probe’s measuring volume. The extracted product can also be diluted with water or other liquids following extraction before passing through the measuring volume. The glass tube in the measuring volume can be adjusted either by eccentric rotation, manually using a lever.

In this way, the probe does not come into contact with the product. The measurement is carried out through the glass tube without contamination. The measurement can be carried out continuously online by extracting the liquid from a process vessel or process line in a bypass flow, and feeding it through the probe’s measuring volume. The extracted product can also be diluted with water or other liquids following extraction before passing through the measuring volume. The glass tube in the measuring volume can be adjusted either by eccentric rotation, manually using a lever. From a cost perspective, it is therefore the ideal compromise for the simultaneous monitoring of several production lines or sampling points where the inline process-monitoring method is too complex or not feasible.

From a cost perspective, it is therefore the ideal compromise for the simultaneous monitoring of several production lines or sampling points where the inline process-monitoring method is too complex or not feasible.